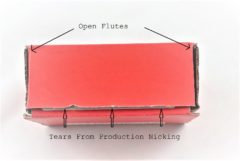

We typically do not criticize the boxes other companies make and use but strictly for educational purposes, we need to point out a few things on the red box shown in the photo.

We typically do not criticize the boxes other companies make and use but strictly for educational purposes, we need to point out a few things on the red box shown in the photo.

- For beginners, the orange/red that flood coats the box’s exterior could have benefitted from a thin layer of an aqueous coating. It is water-based, maintaining sustainability, and even a low-luster coating would have made the red color “pop.” Since this coating is done in line, it would have added minimal cost, if anything.

- The second thing we would have recommended, since this box ships within an outer shipper box, is using a micro, N, or F flute rather than the choice of E-flute. This particular structural design shows the cut edge of the box, so the inner board (fluting or medium) layer is quite visible. There is little attractive about the open edge of any E-flute board.

- Another option would have been to use triple whiteboard so the open, visible edge would be white, not brown, giving the box a more finished look. The photo above shows what that would look like.

- This structural design is often referred to as a top tuck die-cut mailer. A front or cherry lock style design would have looked cleaner by hiding more of the open edges.

- The final suggestion is to lay it out so that the front flap won’t tear when separating the boxes from one another at the packing station. Small boxes are always printed and die-cut in group configurations, such as four-out, six-out, etc. To make sure they transfer through the equipment, they are “nicked” or joined together to stack and palletize more easily. That is all common and normal. However, they can be joined in a way that does not show the rips on the front flap edge. Tears are less visible when placed on a hidden edge rather than the most visible front edge.

BTW, the inside of this particular box has a nice inside print. Unfortunately, the same orange/red color was printed on kraft, which makes the color look muted and dark. Printing on white would have added less than 5% to the overall cost.

There is more to DTC Packaging than many realize

As stated above, this is not to make anyone look or feel bad, so I didn’t identify the company using this box. Instead, I want to point out some of the little things you can do to make a good e-commerce box, a GREAT e-commerce box.

As stated above, this is not to make anyone look or feel bad, so I didn’t identify the company using this box. Instead, I want to point out some of the little things you can do to make a good e-commerce box, a GREAT e-commerce box.

Every year we produce millions of e-commerce boxes for hundreds of companies. That experience has taught us that little things count, and each detail has to be considered for the best result. Nothing truly “wrong” with this box, and it probably satisfies the basic requirements. However, a bit of help could create a better unboxing experience.

E-Commerce packaging guidance is readily available

We invite you to tour our gallery to see some examples of our work for others. Our Branded Packaging Advisors are trained and experienced, and as we always say, this may be your first effort to create a custom DTC shipping box, but it is not ours.

We do this several times a day, and this level of expertise is typically available to you at no additional cost. Most people are pleasantly surprised by the relatively low cost of our custom-designed boxes and inserts.

Call us at 630-551-1700, or contact us through this site. We will be glad to discuss your needs and application with you.

Related posts:

https://www.salazarpackaging.com/intentional-design-for-dtc-e-commerce-packaging/

https://www.salazarpackaging.com/modular-packaging-design-for-e-commerce-dtc-packaging/

https://www.salazarpackaging.com/packaging-triage-and-how-we-fix-what-hurts/