In the last year there has been a large increase in interest by our customers and clients in auto lock shipping containers for DTC order fulfillment. This style of box is known by many names, including “123 Bottom”, “Auto-Lock”, and “Snap Bottom”, to name just a few.

What makes this style different?

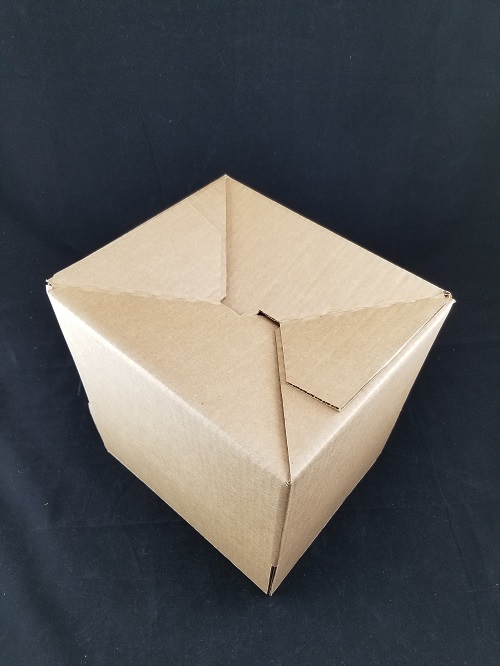

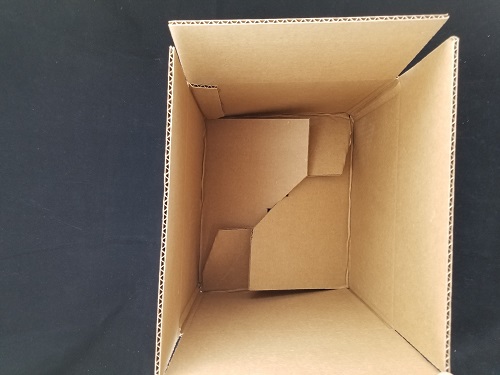

Unlike RSC style boxes with multiple bottom flaps requiring tape for closure and die cut mailers that have no bottom seam at all, auto lock boxes are die cut so they have interlocking flaps across the bottom. When these flaps are folded correctly, they lock in without any type of box sealing tape or adhesive, capable of securely holding even heavy contents through the shipping cycle. The photos included in this post show the before and after of how the bottom box flaps work.

Pre-Folded

Folded but not formed

Formed Inside View

What is the advantage of auto lock bottom boxes?

The primary advantage is that no taping is required. Basic paper or plastic tape is not terribly expensive though often lack of confidence (in the tape being used) leads to multiple layers and strips of tape to make sure the bottom of the box does not come open during handling or shipping. If you are not using a good tape, using more of it, is NOT the right solution but we won’t get into that in this post.

So tape cost can be a factor but the greatest savings is assembly time, and if you are using a 3PL or co-packer, you already know time is money. (See first related post below) The faster a packer is able to form the box you provide, the lower the cost per unit. That may not seem like much but multiply that out times the number of packages per day and per month, it can really add up. You can ask your 3PL to calculate the potential savings that can result.

Do auto lock boxes have any disadvantages?

Compared to standard bottom tape boxes, these are different and do require a little training. After the first awkward few, packers will love how easily and quickly they pop together. Within the industry, we are known for our training videos to help reduce your costs.

The second disadvantage is that since they do not feature a smooth bottom on the inside bottom of the box, some products (very few) are not a good combination. I may not want to use them for packaging paper items (booklets, pamphlets, etc.) or paper clips. The irregular bottom surface may not work best for products that stand vertical or may be unstable. If you have any doubt, send us a photo of your product and tell us your count per case. We will tell you if your application is a good one and create a mock up for you so you can see for yourself.

2023 – the year of e-commerce packaging cost reduction

We predict that the focus of many e-commerce shippers this year will be to reduce OVERALL costs for fulfilling orders. This is simply one of the many ways we can help you accomplish that. Please remember, saving twenty cents on a shipping box is good, but saving $2.00 on 3PL storage and assembly costs, is that much better.

Contact us vis this site or feel free to call us at 630-551-1700 to speak to one of our trained, experienced branded packaging advisors.

Coming up soon – how to dramatically reduce inbound and outbound shipping costs?

Related posts:

https://www.salazarpackaging.com/your-new-2023-dtc-packaging-is-waiting/

https://www.salazarpackaging.com/three-unique-e-commerce-packaging-designs/