Sometimes we in the industry may take for granted our knowledge of the processes of box printing. Many custom packaging buyers may not know the ins and outs of how their boxes are printed, but rather are more focused on bottom-line details such as costs, lead times and of course that all important end result—how their boxes look after production. It’s not at all uncommon for a potential customer to send us a graphic design and ask what it would cost to print. However, it is pretty rare that this same customer would ask us about the specific printing process or the difference between digital printing and flexo printing and which we would use to achieve their desired result.

This is why many box printing companies utilize a fast-quote approach with software designed to give you only the information you want and secure an order as quickly as possible. However, it’s important to note that the information you want, may not in fact be the information you NEED. You may be paying more per box for a design that’s digitally printed, when it could be flexo printed for a fraction of the cost with perhaps a few minor tweaks of the design.

What is Flexo Printing?

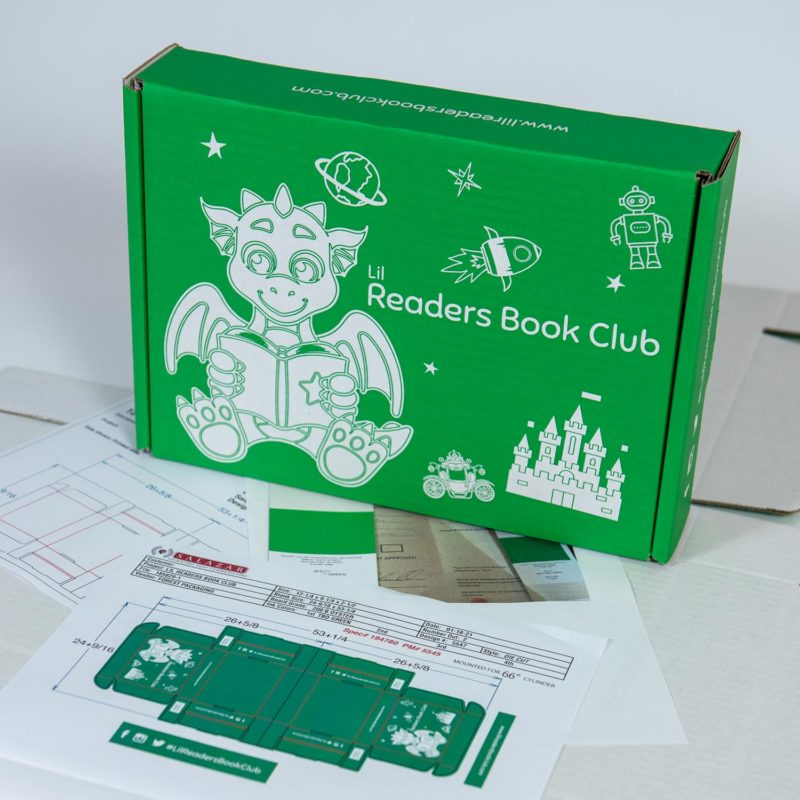

Flexographic printing (flexo for short) is a process by which ink (we use water based inks) is transferred onto the board/box via print plates. You can think of print plates as essentially large stamps. They roll the ink onto the flat, unformed board at high speeds. This requires set up time, but once the equipment is up and running, it may take an hour or less to run several thousand boxes, resulting in substantial savings to you at high volume, large quantity orders. Due to the nature of the process, flexographic printing does have limitations in terms of designs that can be printed. Most 1 and 2 color prints are possible, but in cases with 3 or more colors, especially where there is color overlap, there may be some design tweaking necessary to ensure the best results are achieved on press. For this reason, we always will review artwork at no cost or obligation, and prior to production, we insist on sending a digital print proof as well as ink color swatches for you to approve.

Is Flexo Printing the Lowest Cost Option?

Almost always, yes. Flexo printing is lower by comparison to digital printing on a per unit basis at just about any quantity, but especially at low to mid quantities (between about 1,000 and 10,000 boxes). As a general rule, a flexo printed box will be about half or even as low as a third of the cost of a digital printed box of the same size. What’s more, is that if you are already ordering unprinted mailer boxes at our minimum quantity or higher (1,000 or more), then the cost to add a 1 or 2 color design to your boxes is marginal after the one time purchase of print plates to apply the ink. You could be getting custom branded boxes for much cheaper than you think!

Does Salazar Specialize in Flexo Printing?

We do. But it’s important to know that we have the capability to print digitally as well, so we always like to inform our potential customers of their options and attempt to guide them towards the best print process possible for their given design. We simply have no bias when it comes to selecting a print process, and we will only be fully transparent and provide our industry insight and decades worth of experience to help you make informed decisions. We want you to come back to us with future orders, and this means that our most important goal is for you to love the work we do, and love your boxes. After millions of boxes printed, we are confident in knowing how to best achieve that for you.

Please Contact Us Today

As always, if you have any questions, one of our branded packaging advisors is standing by to assist, with decades of experience behind them. Want to know more about custom packaging options? Please call us at 630-551-1700 or contact us via email at www.SalazarPackaging.com.

Related Posts:

https://www.salazarpackaging.com/faq-varnishes-and-flexographic-printing-of-dtc-packaging/

https://www.salazarpackaging.com/flexo-printing-white-ink-on-kraft-board/

https://www.salazarpackaging.com/which-printing-process-is-best-for-your-e-commerce-box/