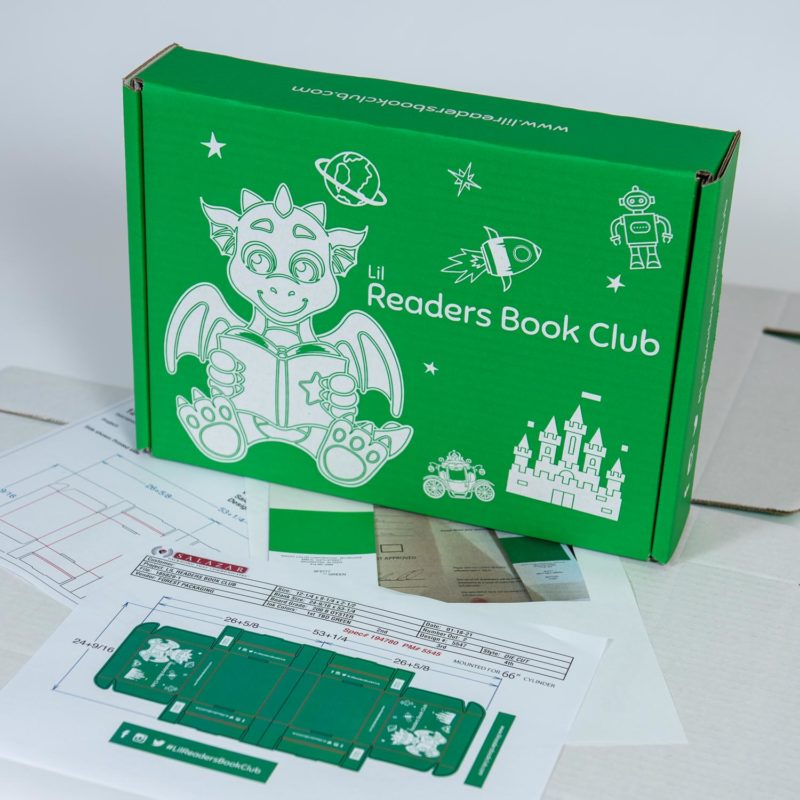

When we do the math, my wife/partner and I have been in the packaging industry over a combined 70 years. Our company, Salazar Packaging is now over 23 years old. That is a lot of experience, watching trends come and go, but what we are most proud of is our accomplishments in the DTC packaging market. We are proud to be a contributor to the internet success of many of our customers, and we are blessed to work doing something we truly enjoy, even after all these years.

A new entrepreneur, recently asked, “what pitfalls should I try to avoid when designing my e-commerce box?” That is a great question and an excellent place to begin what hopefully will be a beautiful relationship. Many inquiries who have never designed a box before are often quick to tell us what they want, and maybe even show us sketches of their self-designed packaging. We want to give our clients everything they want in terms of esthetics, but we believe after millions of boxes made, we are in a slightly better position to handle the structural design part of the project.

Here are some of the most common design mistakes we have seen:

- Creating e-commerce boxes that are too large.

New box designers greatest fear is making a box that is too small. We get that, but many of them end up with a box that is much larger than really necessary. We call that “just in case” shipping box space, and the decades have proven, that additional space is VERY rarely utilized. What does result from using an oversized box is additional inbound shipping cost, higher storage costs, costly void fill or cushioning requiring extra labor, and worst of all, regardless of who is paying for shipping, higher to customer shipping costs.

- Overdoing DTC graphics

Don’t misunderstand, we LOVE printing great looking boxes and as you can see in our gallery, we take great pride in the packaging we produce. However, we often have to remind people that the customers they ship to already know who they are and are probably more focused on the product, rather than the packaging. The other reason to not waste a lot of money on the box exterior, is that it will likely be covered with tape, labels, dirt and scuff marks by the time it arrives. The exceptions to this advice? The e-commerce box interior, and any influencer box. In those two cases, anything goes!

- Making the box overly complicated to assemble

The vast majority of our customers do not do their own order picking and packaging; they utilize a 3-PL, so they can focus on sales and marketing. The problem, as the first “related post” below discusses, costs add up quickly and making the box easy and quick to assembled can save big money on every outbound order.

- Not using the best printing process for the artwork

It stands to reason that a digital printer is likely to suggest, digital printing. A litho label producer needs to sell litho labels. Most of the boxes we print are printed using flexographic equipment and water based inks, though we also create boxes with label and digital as well. The advantage of having all three options is that the application and graphics should always determine the best print process for the job.

- Trying to do everything at once

Ever since we were a start-up company, we have always worked with new entrepreneurs. We certainly understand how unexpected and higher than projected costs can eat away at anticipated profits. We have always been a proponent of enhancing packaging when you can better afford it. The second post below discusses the many things that can be added, post start-up. Things like inside print, inserts, enhanced graphics, etc., can and often times should, be future add-ons to your packaging. When volume grows, future enhancements become much more affordable.

- Not keeping an open mind on design

It is easy to do when you are trying to make a dream, a reality. That is to get fixated on a design that may be fantastic, but not right for your specific product or situation. A great example is the many people who tell us they want “I-phone type packaging for their product”. By that they typically mean, fully lined, soft touch litho labels on a two-piece rigid wall box with insert. We totally understand what the customer envisions, but we also know how expensive that type of packaging can be if it is not being imported from over seas by the container load. Let us help you with options that may be more appropriate at this time.

The most important takeaway from this post, is know who to trust. Our focus is not to create for you the 1,000 most expensive boxes we have ever manufactured. The goal is to help make you successful so you can order tens of thousands of boxes in the near future. Assisting you to minimize your overall costs, may be the best service we can possibly provide you.

Call us at 630-551-1700 or contact us via this site. Our experienced people are standing by to help you determine the best path forward from where you are today, to where you want to be in the near future.

Related post:

https://www.salazarpackaging.com/improvements-and-changes-you-can-make-later-to-your-dtc-packaging/

https://www.salazarpackaging.com/packaging-design-is-not-a-diy-project/

https://www.globeguardproducts.com/industry-experts/packaging-graphic-design-dos-and-donts/