by Dennis Salazar | Oct 18, 2011 | Sustainable Products

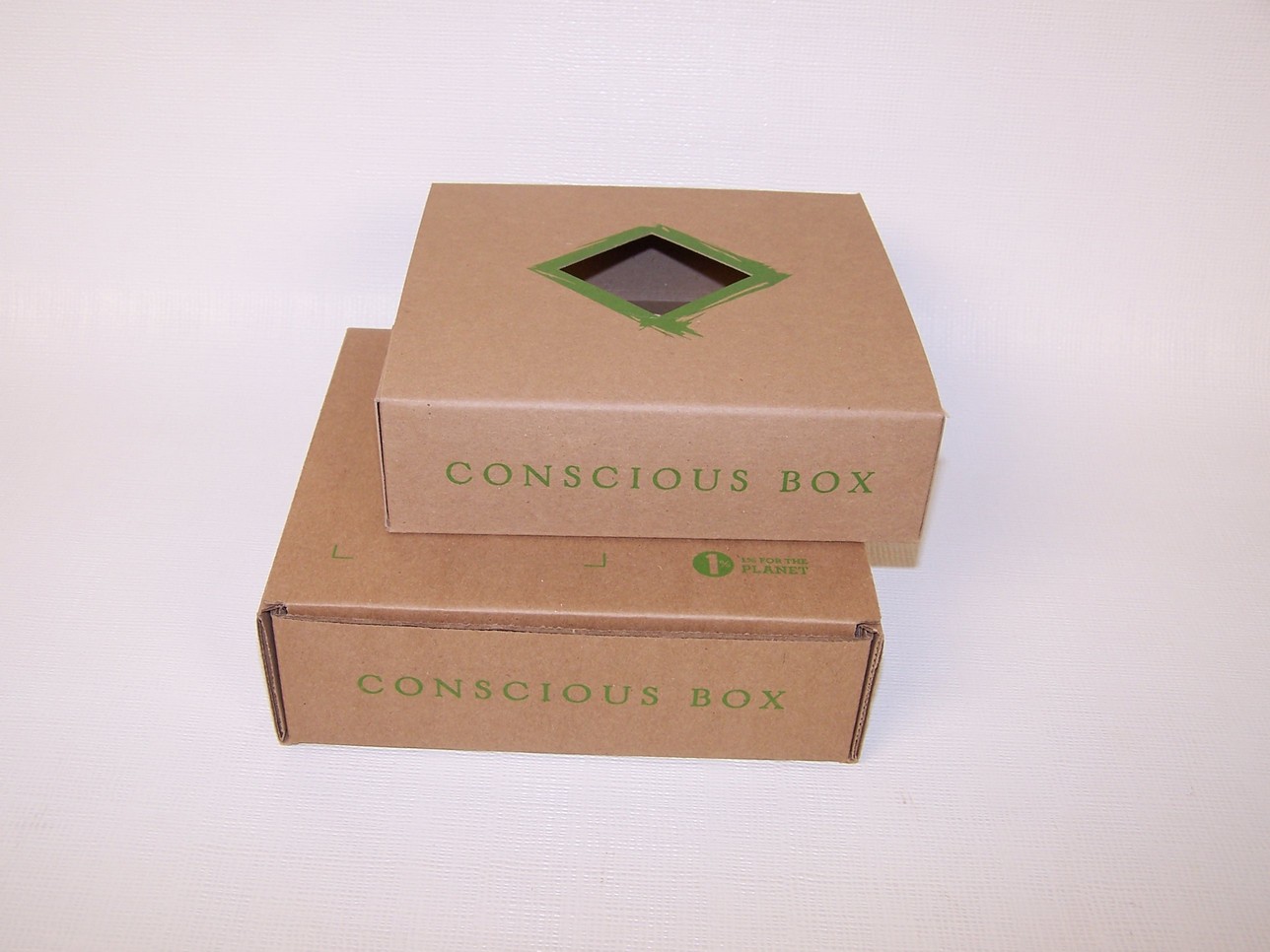

Programs that send new or promotional product samples to the home have been around for a while, but in most cases they are directed and financed by manufacturers eager to get their products into consumers’ hands. The Conscious Box is different in that...

by Dennis Salazar | Sep 30, 2011 | Inside Sustainable Packaging

Corrugated partitions are an excellent green packaging solution because, just like corrugated boxes, they typically have a high recycled content, are reusable, 100% recyclable/repulpable, biodegradable and even compostable. Also, when they are designed and used...

by Dennis Salazar | Sep 20, 2011 | Inside Sustainable Packaging

L’Oreal is serious about sustainability, and that commitment goes well beyond the surface. You might say like beauty, it’s more than skin deep. They have proactively helped lead the cosmetics industry, making their products and primary packaging as sustainable as...

by Dennis Salazar | Sep 13, 2011 | Inside Sustainable Packaging

When the nice people at Hanes first contacted us, they were looking for a product they could use to ship out a sample of their ComfortBlend tee shirt with Eco Smart® fiber for a special promotion. They were absolutely certain about three things: The container or...

by Dennis Salazar | Sep 1, 2011 | Sustainable Products

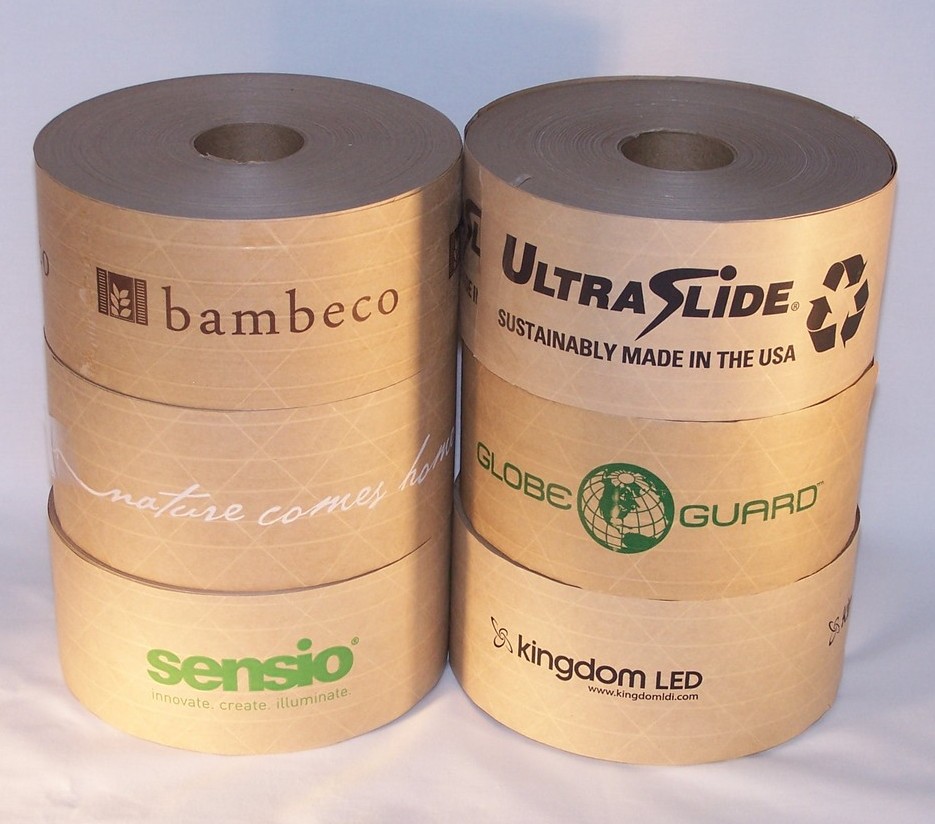

We have met a lot of people who have hesitated to brand their tape because of many misconceptions, including that it’s too expensive or that the minimum quantity required is too large. A very common perception is that the process is too complicated, but nothing could...