The process of creating a packaging design can be like walking through a minefield. If you avoid these 10 packaging design landmines, your new package will provide excellent protection, please customers, and stay well within your budget.

The 10 Biggest Packaging Design Mistakes

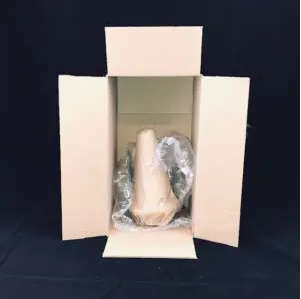

1. Making the packaging too large.

Don’t oversize the dimensions of your packaging “just in case.” Nine times out of 10, the “case” where the larger size is needed never occurs. As a result, the oversized packaging inflates material and shipping costs, along with a number of other downsides.

2. Sizing without considering shipping economics.

Freight costs — for USPS, parcel, and truck shipping — vary depending on package weight and dimensions. Take this fact into account when determining the configuration and count of products to be contained in the package. If you don’t, you could easily end up with a design that substantially and needlessly increases shipping costs.

3. Designing without considering the seal.

Where in warehouse will your shipping box be sealed? What type of sealing method will be used? Will seals be applied manually or with automation? These are critical issues at the packaging design stage. If you fail to think them through, you may have a beautiful package you have no way of economically or reliably sealing.

4. Not considering packing particulars.

Will your boxes be packed by a 3PL or co-packer? These companies charge dearly for poorly designed, non-ergonomic, and time-consuming packaging — it slows down their operation, undermines morale, and sometimes even results in repetitive motion injuries. These problems will occur even if you do the packing on-site, but they won’t be as obvious because you won’t be billed for them.

5. Using too much ink.

Exterior printing on small boxes, in whatever color, results in nothing but red ink on your income statements. Why? Because shipping labels and/or adhesive box sealing tape will cover most of your message. One way we overcome this landmine for customers with a real need to communicate something is to print the box sealing tape.

6. Not providing an easy open.

Customers love an easy-opening package but trying to add a tear strip or easy-open perforation after the original design is in production is difficult and expensive. Avoid the temptation to minimize cost by failing to incorporate an easy-open feature: you’ll be sorry you did once you start getting negative or indifferent feedback from customers.

7. Starting with too many sizes.

Don’t start with all sorts of sizes with your new packaging design, in anticipation of hot sales across the board. We have found again and again it is more prudent and cost-effective to start with a small number of variations until you know which of your products are selling and which are not. Trying to cover all the bases perfectly at the outset almost always results in wasted money and dead inventory.

8. Assuming instead of asking.

There’s no need to assume what kind of packaging design your customers will like because you can ask them. There’s no need to assume your customers have no special requirements for packaging, shipping, or receiving because you can ask them. When you involve customers in the design process, it’s like having a precise map to navigate your way through the designing minefield.

9. Overcomplicating.

The simpler the packaging design, the better. Simple is less expensive. Simpler is easier to set up, pack, seal, and ship. Simpler is usually more eco-friendly and almost always more user-friendly. Designers, marketers, and engineers — three teams typically involved in packaging design and redesign projects — might overcomplicate things without a few gentle reminders.

10. Not evaluating the design.

After your new packaging design has seen some action in the field, do you deem it a success, a failure, or a work-in-progress? Your design project isn’t over until you can make this assessment. Quite frequently, a few minor and inexpensive tweaks can turn a good package into a world-beater.

Let’s Talk!

We help our customers create and improve packaging design 24/7 — it’s our passion. If you are starting a new packaging design or redesign project, we need to talk!

Please call us at 630-551-1700 or contact us through the website to start the conversation.

Related Posts:

https://www.salazarpackaging.com/10-common-mistakes-dtc-start-ups-make-on-social-media/

https://www.salazarpackaging.com/the-high-cost-of-your-outdated-e-commerce-packaging-design/

https://www.salazarpackaging.com/creative-dtc-packaging-design-now-can-create-huge-savings-later/