If your current packaging design is more than a few years old, it was probably made at a time when corrugated costs were low and to be frank, the price of your shipping box was of little consequence when your business was growing in leaps and bounds. Today, with increased competition, and higher prices on everything, everyone is looking closer at all costs.

Most e-commerce shippers would agree, other than your product cost and actual shipping cost, packaging materials are probably the single largest expense. The fact is that post-Covid, the corrugated industry has increased pricing a whopping nine times. So, it is very likely your packaging design reflects a focus on initial esthetics, rather than current economics. Those nine industry price increases have made your packaging more expensive than it needs to be.

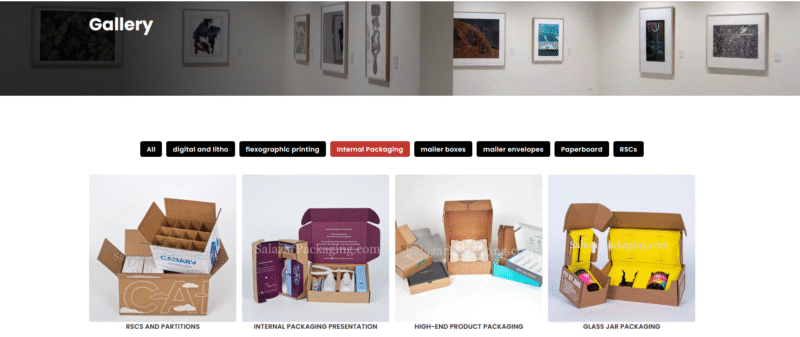

Great Looking Packaging at a Great Price

We believe most industry experts would agree we have helped customers produce some of the most attractive and memorable packaging the e-commerce market has ever seen. Check out our gallery for a look at some of the work we have done for others. What you don’t see there is the time we have spent making this DTC packaging as economical as possible by minimizing:

Per unit cost

Right-sizing for lowest cost making your packaging as sustainable as possible. It is possible if not probable, the box size that was perfect four years ago is now oversized. The additional board used adds cost and makes your packaging less sustainable

Inbound shipping cost

This is the cost of getting your packaging from our plant to you or your 3PL. A smaller, more material economical design usually produces a lower shipping cost because it enables us to place more boxes (or inserts) per pallet.

Storage costs

One of the greatest challenges is balancing packaging inventory expense with your anticipated needs. So, carrying an abundance of packaging is a costly but necessary requirement. 3PL space costs money usually on a per pallet monthly basis.

Labor cost

Even if you are doing your own order fulfillment in house, reducing the time spent handling, assembling and forming your packaging is critical to your profitability. That is most obvious when your packaging and shipping is being performed by a 3PL.

Outbound shipping cost

Whether you or your customer are paying for shipping, making this expense as low as possible is imperative. It also makes it easier for you to compete with competitor’s “free shipping” offers.

Business Has Changed for All of Us

Products and entire product lines can change. Customer order quantities, or product combinations may be different than they were just a few years ago. That five pack you hoped would be the standard is rarely ordered but your three pack is by far your most popular customer choice.

We have worked with hundreds of start-up companies and most begin by doing their own warehousing and fulfillment. Some will eventually utilize a copacker or 3PL, and others choose to work with Amazon to satisfy their customers’ orders. If you are one of those companies, you know what SIOC (Ships in Own Container) means and realize the importance of creating packaging that is minimal but is able to withstand the multiple handling of their products. Those qualities may not exist in your initial packaging design.

Structural Redesign versus Graphic Redesign

Most people know we are NOT graphic designers. We can connect you with a great graphic artist, if you need one, but we admit that is not where our expertise and experience lies. What we are really, really good at is designing and redesigning packaging that saves our customers money in every way possible. BTW, when you are thinking about a graphic brand refresh or logo/artwork change, is the perfect time to also review your structural design as well.

Making structural changes to your current design can be expensive but it does not have to be. Some modifications are cost-free, and a good packaging partner can help you minimize the cost of print plates or cutting dies if necessary. When contemplating the potential cost of a redesign, consider how much it is costing you to NOT redesign or update your e-commerce packaging. Your profitability can be negatively impacted in many ways and we are the company able to show you where and how that cost can be minimized or in some cases totally eliminated.

There is no cost for conversation, and we would love to discuss the specifics of your business today. Call us at 630-551-1700 or contact us via this link to discuss your packaging with one of our experienced branded packaging advisors.

Related posts:

https://www.salazarpackaging.com/top-ecommerce-packaging-trends-for-2026-and-lessons-from-2025/

https://www.salazarpackaging.com/how-shifts-in-consumer-purchasing-impacts-e-commerce/

https://www.salazarpackaging.com/how-a-good-packaging-design-can-reduce-your-3pl-costs/