by Dennis Salazar | Jul 19, 2017 | Sustainable Perspective, Information Center

How many different size e-commerce shipping containers do you really need? They say variety is the spice of life but in packaging, it can hurt your bottom line if the wrong decision is made. The typical e-commerce shipper has two options: Utilize more, different sizes...

by Dennis Salazar | Jul 21, 2015 | Sustainable Products

Is there anything more disappointing than opening up an eagerly anticipated e-commerce or subscription box package only to find everything that was carefully packed is now an unrecognizable heap? Many of our customers work very hard to create a great presentation for...

by Dennis Salazar | Apr 5, 2011 | Sustainable Products

A quick look at today’s headlines or the nearest gas pump confirms oil prices are on a steep rise, which ultimately impacts natural gas and plastic resin prices as well as everything we buy or use that contains plastic. Experts tell us there is no end in sight, so as...

by Dennis Salazar | Mar 10, 2011 | Inside Sustainable Packaging

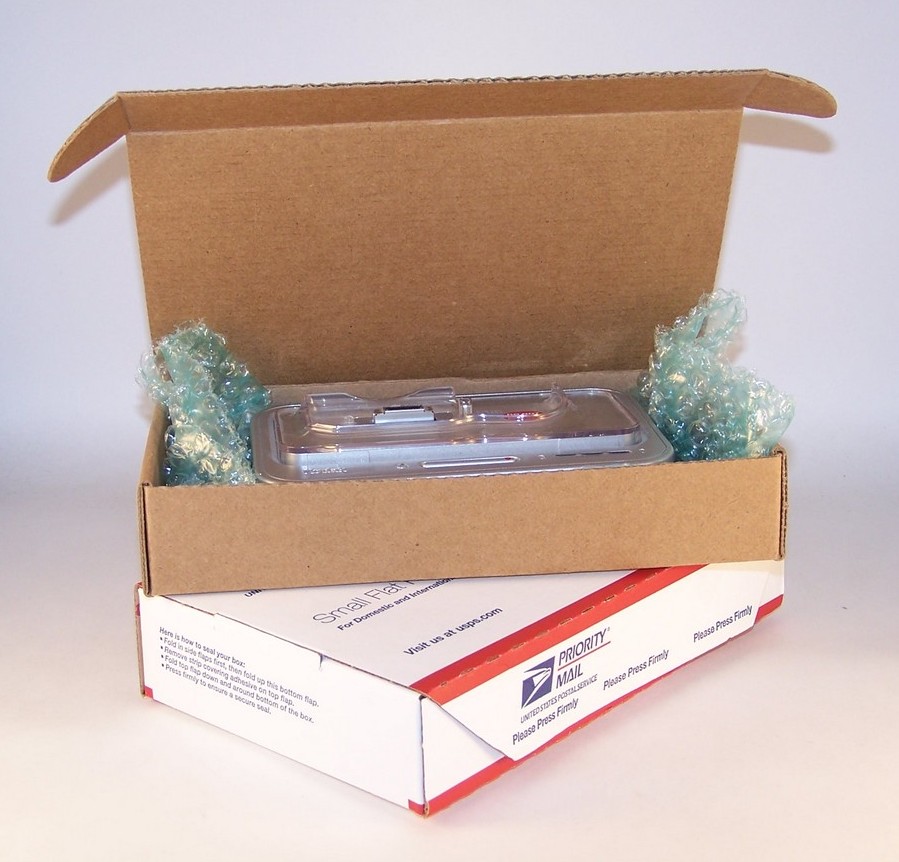

As a substantial U.S. Postal Service rate increase goes into effect on April 17, many in the mailing and fulfillment industry are seeking ways to help minimize the increase, or better yet, reduce costs. Packaging can be an important component in that effort and will...