We manufacture a wide range of internal, protective packaging solutions but one that seems to be a well-kept secret is our expertise in partitions. For the right application, they can be a very versatile, and low cost, protective packaging option. Here are a few things you may not know that can potentially help you get the job done and save you money at the same time.

- Not just for multiples of the same round item.

Most people are only familiar with partitions as dividers for bottles and cans. The soft drink and liquor industries typically use millions of them. However, the shape of the products being shipped can be anything, if all it needs is separation.

- Paperboard or corrugated?

Corrugated board is most often used for making partitions, especially when the products being shipped are heavier and require more protection. Even paper and metal cans can be dented, especially aluminum containers. Paperboard partitions are lower in cost and take up less space in storage or the box being shipped.

- Partition board type, weight and grade.

Partitions are custom in terms of material. Whether you require corrugated or paperboard, each is available in just about any type you need for whatever application you have.

- No tooling required.

While most custom packaging products do require costly cutting dies, partitions are made on equipment able to cut different patterns as needed without any type of tooling. That can save thousands compared to other custom packaging.

- Don’t forget the perimeter air cell.

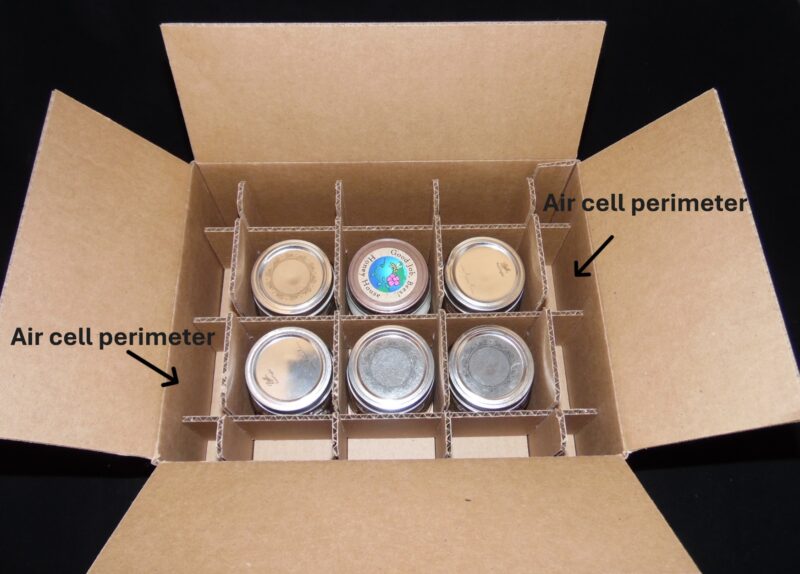

When you see a narrow empty cell around the perimeter of any box and partition combination (see photo), it is there to provide extra protection for the products being shipped. That area serves as a shock absorber or “crush zone” designed to give in, before your product is impacted.

- Saving the best for last: No assembly required!

We still run into a customer now and then who does not realize that partitions are available preassembled. There is no question that assembling partitions can consume valuable time for your packers or worse yet require an additional person to put them together while another person does the packing. Since the partitions are assembled at high speeds by special equipment at the plant, the additional cost to you is minimal.

Flat assembled partitions

Formed Assembled Partition

Are partitions the best option for you? Possibly. Or perhaps a simple divider or insert will be lower in cost and easier to use? You cannot be sure until you have a discussion with one of our trained, experienced application experts.

Call us at 630-551-1700 or contact us for a no cost, no obligation application review.

Related posts:

https://www.salazarpackaging.com/sustainable-packaging-solution-corrugated-partitions/

https://www.salazarpackaging.com/why-add-internal-packaging-in-your-e-commerce-shipping-boxes/