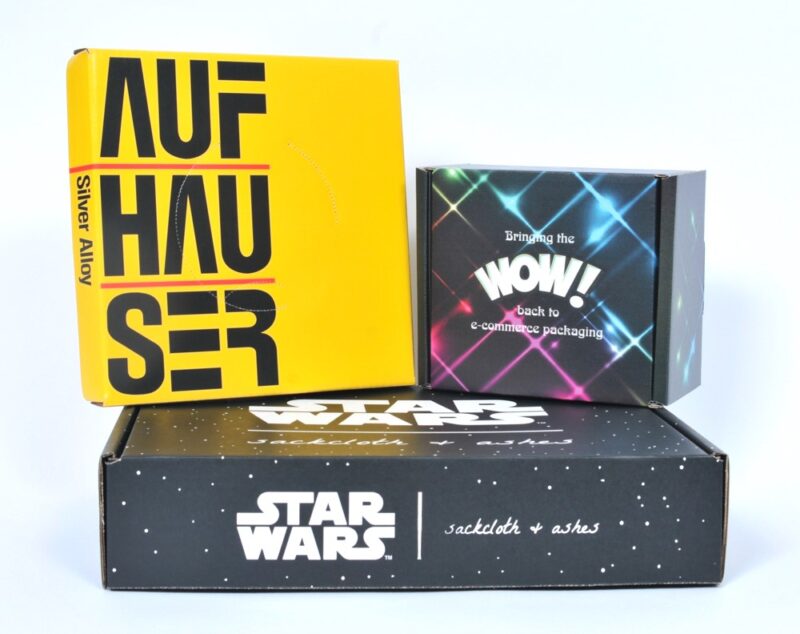

As most of our regular readers know, we help our customers create DTC packaging that will display their product attractively, protect it during transit, and do so at the lowest possible cost.

Every application and customer’s expectations are unique, so there are dozens of details that have to be considered when producing a great design. However, experience tells us the following four are the most frequent and apply to all applications. They are:

- Custom Printing Process Choice

We offer three of the most popular printing options available – flexographic, digital and litho label. Which print option is best for you is usually determined by your graphic design, and that decision will lead to everything else including board and ink type that should be used for optimal results.

- Board Type, Grade and Color

Board type and grade are usually determined by the specific application and as described above, the chosen graphic process. Application factors include the product being shipped, product count, product weight, and how it is going to be shipped. The board color chosen, kraft or white, depends on the graphic design and finish.

- Inserts, Dividers, and Partitions

Though most of these internal packaging options can be added in the future, adding them later may require resizing or redesigning. So, if possible, planning now during the initial design phase for possible addition later can help avoid expensive items such as new cutting dies or print plates.

- Features That Are Easy to Add Now

The best thing about custom packaging is the ability to add options that really make your boxes unique and more customer and packer friendly. This includes features like peel and seal closures, and easy open perforations will help reduce packing time. Easy open features also receive great reviews from customers.

These are indeed just the basic four things to consider, but it can get much more complicated, depending on many other application factors. While we always appreciate the thought and pre-planning any customer puts into their new design, as we often say, packaging is not a DIY project. This is why experience really makes a difference.

Call us at 630-551-1700 or contact us via this web site. Someone from our team, maybe me, will be glad to discuss your project with you, and will help you get started.

We truly enjoy what we do and are committed to making this a positive, rewarding process for you. Yesterday I participated in a Zoom call with a terrific young couple ready to create their new subscription box. The lady ended our conversation by saying, “We are so glad we found you”. That makes all the work and effort worthwhile.

Related posts:

https://www.salazarpackaging.com/blog/beginners-guide-to-e-commerce-packaging-design/

https://www.salazarpackaging.com/blog/how-a-good-packaging-design-can-reduce-your-3pl-costs/

https://www.salazarpackaging.com/blog/packaging-design-is-not-a-diy-project/