Most people agree the print quality of our e-commerce boxes is what sets us apart from other box producers. The correct printing process, on the right equipment, combined with the best substrate and inks, will indeed produce the best and desired results.

However, what is not as obvious or visible are the ingeniously simple structural designs we create for our customers. We demonstrate how good internal packaging does not have to be complicated or expensive. However, well designed protective and interior packaging can reduce costs for years to come, on every single package they buy and ship. Those savings will be delivered in many ways, including:

- A substantial reduction in 3PL expenses resulting from reduced storage fees, and in many cases a dramatic labor savings! (see first Related Post below)

- Shipping savings on dimensional rates by making your item as compact as possible.

- Reduction or elimination of damage claims and all the resulting expenses including credit, replacement, negative customer feedback, etc.

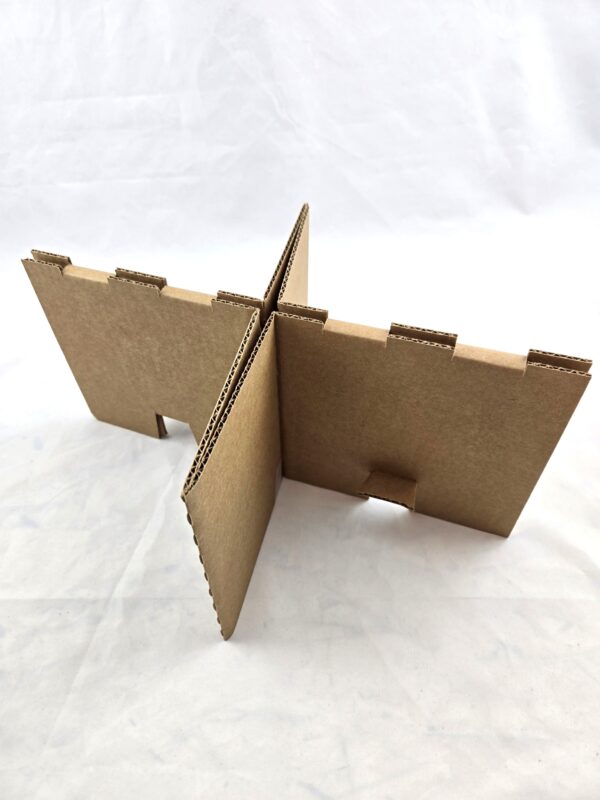

- Elimination of interior, ancillary packaging. BTW, our definition of ancillary is “unnecessary”. No paper, foam or bubble needed!

Pay Me Now or Pay Me Later

In 1972 Fram oil filters launched an advertising campaign that included a TV commercial featuring an auto mechanic performing a $200 bearing job on a customer’s engine. FYI, that would be over $1,500 today.

The claim was installing a $4.00 Fram oil filter could have saved the customer a very expensive repair later. The point of the story is that sometimes and still today, spending a little up front can minimize or eliminate a much bigger or repetitive cost later.

In terms of packaging design and creating an insert or divider, there may be some unexpected cost for tooling but usually it is minimal, and it is a one-time expense. Ongoing, operational future expenses on the other hand tend to be forever. Packing labor is certain to be more expensive in the years ahead. The mills who make corrugated board used to make boxes are certain to continue their annual price increases. And shipping is not likely to become less expensive.

So, if you are creating packaging to serve you well for years to come, utilizing a company like Salazar Packaging today, to can save you a huge amount of money over time.

How Do We Produce Savings for You?

There are several areas where costs that can be managed and minimized:

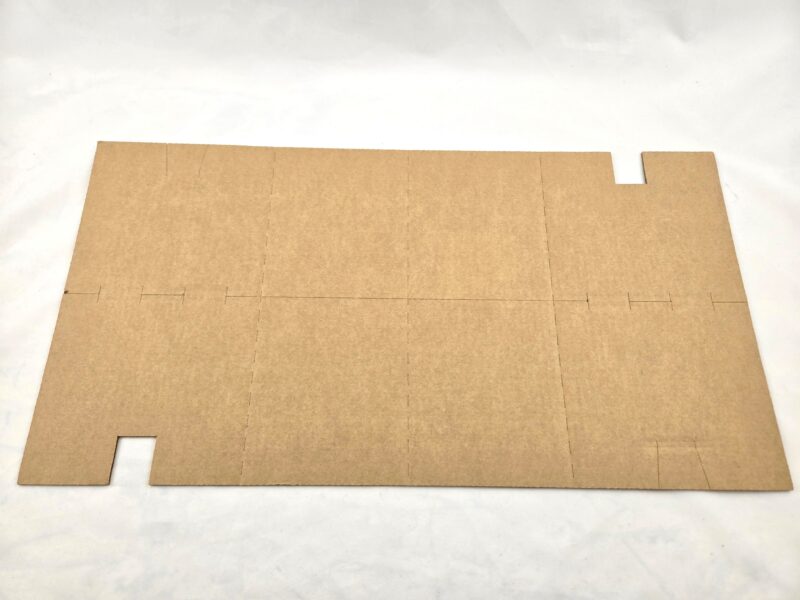

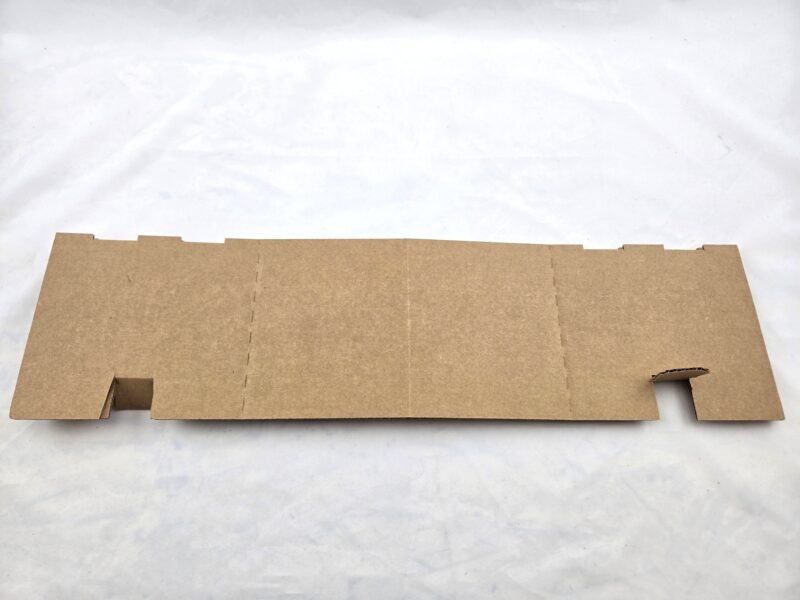

Corrugated board – keep it simple. Remember e-commerce box and insert pricing is always calculated based on the number of square inches used. So, our objective is always to help you use minimal board.

Packaging storage – Check the second related post below to read about storage costs at your 3PL or contract packager. Per pallet expenses add up quickly, so fewer stock pallets results in lower monthly expenses. Void fill materials like bubble wrap or cushion wrap are incredibly expensive to ship and store.

Packaging costs – make internal packaging as easy to assemble as possible. Many 3PL companies use day labor to satisfy varying customer volumes, so the KISS principle is a must. Not to mention what happens when a protective insert is assembled incorrectly? Usually, the product being shipped arrives damaged.

This is just a snap-shot view of a much more potentially complicated problem. Let us make it as easy and simple as possible and show you what you can do to save you money in the long run. Call us at 630-551-1700 or contact us via this link.

We look forward to working with you on your project.

Related Posts:

https://www.salazarpackaging.com/blog/how-a-good-packaging-design-can-reduce-your-3pl-costs/

https://www.salazarpackaging.com/blog/beginners-guide-to-e-commerce-packaging-design/